Frame machine repair focuses on restoring structural integrity through meticulous inspections and addressing damage in the vehicle's frame, chassis, suspension, and wheels. Skilled technicians use specialized tools like CAD technology and laser measures to identify and fix hidden issues, realign components, and fine-tune suspension for accurate alignment, ultimately enhancing safety and aesthetics.

In the realm of machinery maintenance, proficient frame machine repair is paramount for ensuring equipment longevity. This article delves into the critical components that technicians scrutinize during repair jobs. We explore the essential process of understanding and diagnosing issues within a frame machine, emphasizing a comprehensive inspection to identify damage and wear. Further, we highlight precision techniques to restore functionality, underscoring the importance of meticulous craftsmanship in these repairs.

- Understanding Essential Components of Frame Repairs

- Comprehensive Inspection: Identifying Damage and Wear

- Precision Techniques for Restoring Machine Functionality

Understanding Essential Components of Frame Repairs

Understanding Essential Components of Frame Repairs

When it comes to frame machine repair, several key components demand meticulous attention. The primary focus is on ensuring structural integrity, which involves inspecting and addressing any damage or misalignments in the vehicle’s frame. This includes checking for bent or broken parts, as well as proper alignment of the chassis, suspension, and wheels. A comprehensive assessment is crucial to guarantee that the vehicle maintains its safety and handling capabilities after repairs.

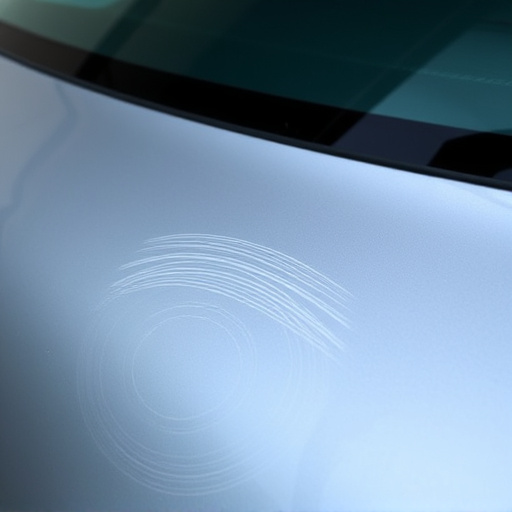

Additionally, skilled technicians delve into components like welds, bolts, and mounting points, ensuring they are secure and in optimal condition. Proper repair techniques for dent removal or collision damage play a significant role here. By addressing these essential elements, a collision repair center can effectively restore the vehicle body repair to its pre-incident state, enhancing both performance and aesthetics.

Comprehensive Inspection: Identifying Damage and Wear

A comprehensive inspection is a crucial step in any frame machine repair job, serving as the foundation for effective and accurate repairs. This meticulous process involves a thorough examination of the vehicle’s frame to identify signs of damage, wear, and potential safety hazards. Skilled technicians utilize specialized tools and their expertise to uncover hidden issues that might not be immediately apparent. From minor cracks and dents to more significant structural damage resulting from vehicle collisions or accidents, every detail is carefully assessed.

During this inspection, auto repair services professionals pay close attention to the frame’s alignment, checking for any misalignments or uneven gaps. They also inspect the components of car restoration, such as the suspension system, joints, and bolts, ensuring everything is in proper working order. This comprehensive evaluation enables technicians to create a precise repair plan, addressing not just visible damage but also underlying structural integrity issues, thereby guaranteeing a safer and more reliable vehicle following the frame machine repair process.

Precision Techniques for Restoring Machine Functionality

Precision is paramount when it comes to frame machine repair, as it involves meticulous techniques to restore a vehicle’s structural integrity. Skilled technicians employ specialized tools and equipment to accurately measure and adjust various components, ensuring the car’s frame is aligned correctly. This process includes realigning the chassis, straightening bent panels, and fine-tuning suspension systems.

Effective frame machine repair requires an understanding of advanced auto body repair methods, such as computer-aided design (CAD) technology and laser measuring devices. These tools enable technicians to pinpoint exact dimensions, identify subtle misalignments, and make precise adjustments. Consequently, it facilitates the seamless integration of car paint services during the restoration process, guaranteeing a flawless finish that enhances both aesthetics and safety in an automotive body shop environment.

In conclusion, successful frame machine repairs hinge on meticulously evaluating key components, identifying damage, and employing precision techniques. By thoroughly understanding the essential parts of a frame machine and implementing comprehensive inspection methods, technicians can restore functionality effectively, ensuring these machines operate at peak performance for years to come. This multi-step approach is vital for any frame machine repair job, guaranteeing both quality and longevity.