Frame machine repair is vital for vehicle safety, requiring adherence to industry guidelines and advanced techniques like laser alignment. Technicians must be skilled, stay updated with standards, and maintain meticulous records. Compliance involves thorough inspections, referring to recognized standards, using certified staff, proper disposal of hazardous materials, and detailed documentation throughout the process. Best practices include digital tracking systems for every repair step, ensuring current industry standards and customer satisfaction while serving as a safety net during audits.

In the precision-driven world of manufacturing, adhering to frame machine repair standards is paramount. This article guides you through essential aspects of ensuring compliance with industry guidelines during the repair process. We delve into understanding key repair standards, outlining step-by-step compliance strategies, and exploring best practices for meticulous documentation and maintenance. By implementing these measures, workshops can uphold excellence in frame machine repairs, fostering efficiency and safety across industries.

- Understanding Frame Machine Repair Standards

- Steps to Ensure Compliance During the Repair Process

- Best Practices for Documenting and Maintaining Compliance

Understanding Frame Machine Repair Standards

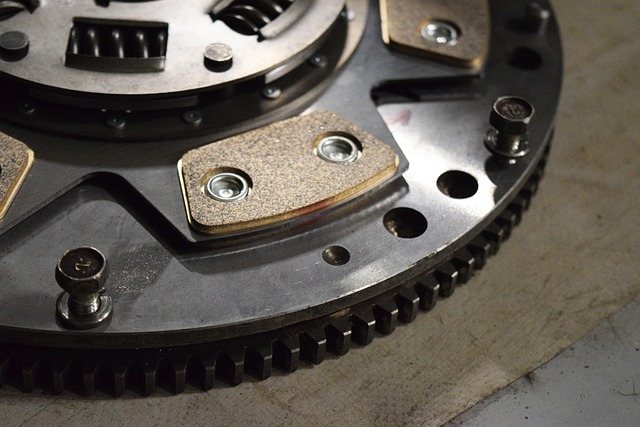

In the realm of automotive maintenance, frame machine repair stands as a critical aspect of ensuring vehicle safety and structural integrity. Adhering to industry guidelines is paramount for any vehicle body shop or collision center aiming to deliver top-notch services. These standards are designed to guarantee that frame straightening procedures are executed with precision and consistency, minimizing the risk of future structural issues. By following these protocols, skilled technicians can effectively address damage caused by accidents or normal wear and tear, restoring vehicles to their original specifications.

Comprehending the nuances of frame machine repair involves familiarizing oneself with various guidelines and best practices. This includes knowing when to apply specific techniques, such as laser alignment or robotic welding, to ensure accurate results. Furthermore, understanding the interconnection between frame straightening and other collision center services is vital for comprehensive vehicle restoration. Skilled professionals in these facilities must stay abreast of evolving industry standards to maintain compliance and deliver exceptional service quality in their frame machine repair practices.

Steps to Ensure Compliance During the Repair Process

To ensure compliance with industry guidelines during a frame machine repair, follow these crucial steps. First, thoroughly inspect the damaged frame using specialized tools and techniques to accurately assess the extent of the damage. This involves identifying any misalignments or deformities in the vehicle’s structural components. Once the assessment is complete, refer to recognized industry standards and guidelines for the appropriate repair procedures specific to different vehicle makes and models.

Next, employ certified and skilled technicians who are well-versed in frame straightening techniques and auto body repair. They should use advanced equipment like laser alignment tools to ensure precise adjustments. During the repair process, maintain detailed records of all work performed, parts replaced, and measurements taken. This documentation is vital for verifying compliance and serving as a reference for future maintenance or repairs. Additionally, adhere strictly to environmental regulations by properly disposing of any hazardous materials generated during the frame machine repair process.

Best Practices for Documenting and Maintaining Compliance

Maintaining compliance with industry guidelines during frame machine repair is a meticulous process that demands precision and thorough documentation. Best practices involve establishing a comprehensive system for tracking every step of the repair process, from initial assessment to final quality check. This includes maintaining detailed records of parts used, work performed, and inspection outcomes. Utilizing digital platforms or specialized software can streamline this process, making it easier to access and update information quickly.

Regularly updating documentation ensures that all repairs adhere to current industry standards, which is vital for providing high-quality vehicle repair services, auto body services, and ensuring customer satisfaction. Moreover, meticulous record-keeping serves as a robust safety net in case of scrutiny or audits, demonstrating compliance with regulations and best practices in frame machine repair.

Frame machine repair compliance is not just a technical requirement but also ensures the safety and efficiency of your equipment. By understanding industry guidelines, following meticulous repair processes, and adopting best practices in documentation, you can maintain optimal performance standards while adhering to relevant regulations. This comprehensive approach not only safeguards your machinery but also enhances its longevity, ultimately contributing to improved productivity.