Advanced frame machine repair in auto shops leverages AI, PDR, and modern tools for precise, efficient, and high-quality car body restoration. These innovations streamline operations, reduce costs, enhance safety, and enable mechanics to proactively identify vehicle issues. The evolving field requires skilled technicians with training in CAD software and state-of-the-art frame machines to meet the demands of modern vehicle technologies.

The auto industry is on the cusp of a new era in frame machine repair, with advanced technologies and equipment transforming how auto shops address structural damage. This article explores the future of frame machine repair, focusing on evolving technologies, the benefits of cutting-edge tools, and the training needs for the next generation of technicians. Discover how these innovations are revolutionizing the process, ensuring safer, faster, and more accurate repairs.

- Evolving Technologies in Frame Repair

- The Benefits of Advanced Equipment

- Training and Skills for Future Technicians

Evolving Technologies in Frame Repair

The future of frame machine repair in auto shops is bright and dynamic, driven by technological advancements that are transforming the way damage is assessed and repaired. Modern frame machines now incorporate sophisticated sensors and AI algorithms to accurately detect even subtle misalignments, ensuring precise repairs that meet the highest industry standards. These innovations have significantly reduced the time and cost associated with traditional frame repair methods.

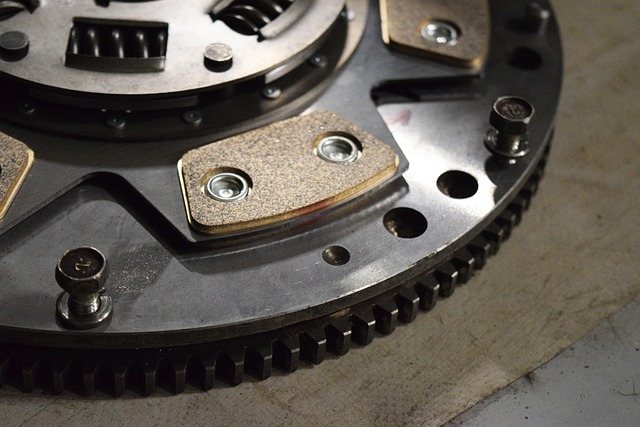

One notable trend in evolving technologies is the integration of paintless dent repair (PDR) techniques, which minimize the need for extensive painting and body work. Additionally, tire services are becoming more integrated into auto shop operations, offering one-stop solutions for customers. Car body restoration processes are also seeing a boost from advanced tools and materials, enabling shops to deliver high-quality, aesthetically pleasing results faster than ever before.

The Benefits of Advanced Equipment

In today’s digital era, auto shops are increasingly embracing advanced equipment for frame machine repair, revolutionizing how they address structural damage in vehicles. These modern tools offer precise measurements and adjustments, enabling technicians to perform intricate repairs with enhanced speed and accuracy. The adoption of cutting-edge technology not only improves the quality of frame restoration but also streamlines the overall repair process, leading to reduced turnaround times for car dent repair and improved efficiency in auto body services.

Moreover, advanced equipment facilitates a more comprehensive approach to auto maintenance. By providing detailed insights into vehicle frames, these tools help mechanics identify potential issues early on, preventing further damage. This proactive approach not only saves costs for both the shop and its clients but also ensures safer and more reliable vehicles on the road. In terms of benefits, frame machine repair with advanced equipment is undoubtedly a game-changer in the auto industry, setting new standards for quality and efficiency in auto body repairs.

Training and Skills for Future Technicians

As the field of frame machine repair evolves, so does the skill set required for technicians. The future of auto shops lies in training and educating a new generation of professionals who can adapt to advanced technologies and innovative repair methods. With the increasing complexity of vehicle designs, especially in terms of safety features and lightweight materials, technicians must be adept at handling delicate frame repairs while ensuring precision and accuracy.

The training should encompass both theoretical knowledge and hands-on experience. Future auto body repair technicians will benefit from learning computer-aided design (CAD) software for precise measurements and virtual prototyping. Additionally, practical training on state-of-the-art frame machines, including their operation, calibration, and maintenance, is essential. This ensures that technicians are well-equipped to handle modern vehicle bodywork repairs, keeping up with the ever-changing demands of the automotive repair services industry.

The future of frame machine repair in auto shops lies in embracing advanced technologies and equipment, which offer faster, more precise results. As technology evolves, technicians will need to adapt and acquire new skills to stay relevant. Investing in training ensures a competent workforce capable of handling complex repairs efficiently. With the right tools and knowledge, auto shops can provide top-quality frame machine repair services, enhancing customer satisfaction and maintaining vehicle safety standards.