Frame machine repair is a critical, game-changing aspect of automotive maintenance that enables collision repair centers and auto body shops to provide efficient, safe, and high-quality services. Regular maintenance ensures structural integrity, streamlines workflows, reduces customer downtime, and enhances satisfaction in a competitive market. This proactive approach maximizes shop efficiency, productivity, and equipment longevity, leading to better output and satisfied customers.

In the competitive landscape of shops and workshops, efficient and safe operation is paramount. Frame machine repair plays a pivotal role in achieving this, yet it’s often overlooked. This article delves into the crucial aspects of frame machine maintenance, highlighting its impact on shop efficiency, safety, and cost-effectiveness. By exploring regular repairs, potential hazard mitigation, and long-term savings, we emphasize why investing in frame machine repair is a strategic move for any business aiming for sustained success.

- The Role of Frame Machine Repair in Maintaining Shop Efficiency

- – The impact of well-maintained frame machines on workflow speed and product quality

- – Reduced downtime and increased productivity through regular repairs

The Role of Frame Machine Repair in Maintaining Shop Efficiency

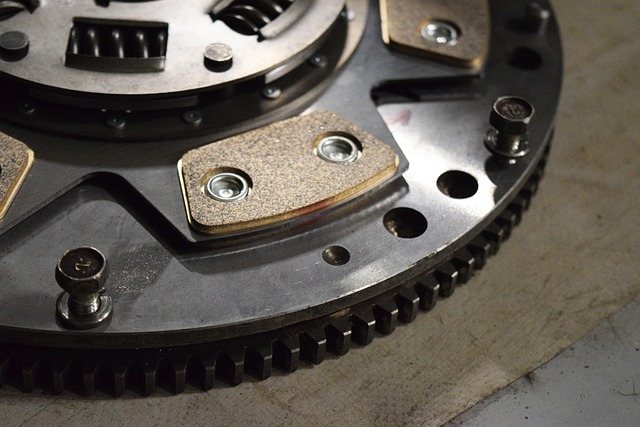

In the realm of automotive maintenance and repairs, frame machine repair plays a pivotal role in keeping shops efficient and effective. This specialized service is essential for any collision repair center or auto body work facility aiming to deliver top-notch services. By focusing on frame machine repair, these centers ensure that vehicles’ structural integrity is restored accurately, which is crucial not just for safety but also for the longevity of the vehicle. A well-maintained frame ensures that all subsequent auto detailing and auto body work are done on a solid foundation, saving time and resources in the long run.

Moreover, regular frame machine repair enables these centers to minimize downtime for customers. Efficient repairs mean faster turnarounds, keeping the shop bustling and meeting the demands of modern drivers who value their time. This not only enhances customer satisfaction but also contributes to the overall success and competitiveness of the collision repair center or auto body work facility in a crowded market.

– The impact of well-maintained frame machines on workflow speed and product quality

In any collision repair shop or car paint services, the frame machine plays a pivotal role in vehicle bodywork restoration. Well-maintained frame machines ensure precision and accuracy during the alignment process, directly impacting workflow speed and overall product quality. When these machines are regularly serviced and repaired as needed, they maintain their optimal performance, enabling faster turnaround times for repairs and enhancing the shop’s efficiency.

This is particularly crucial in keeping up with customer demands and maintaining a competitive edge in the market. Efficient frame machine repair not only saves time but also ensures that each vehicle undergoes the necessary bodywork treatments consistently, resulting in superior repair outcomes and satisfied clients who return for future car paint services.

– Reduced downtime and increased productivity through regular repairs

Regular frame machine repair is a cornerstone for any shop looking to maximize efficiency and productivity. By addressing potential issues early through professional car body restoration services, shops can significantly reduce downtime that often occurs when frame machines are left untended. This proactive approach ensures that equipment remains in top working condition, allowing for seamless operations and faster turnaround times on repairs like car dent repair or Mercedes-Benz repair.

A well-maintained frame machine plays a pivotal role in the overall productivity of a shop. It enables technicians to perform tasks with precision and speed, directly translating into increased output. This is particularly crucial in competitive markets where customer satisfaction often hinges on timely service. Thus, investing in routine frame machine repair is not just a maintenance measure but a strategic decision that fosters sustainability and growth in the long run.

Frame machine repair is a vital aspect of shop maintenance that often goes overlooked. However, its impact on overall efficiency cannot be overstated. By prioritizing regular frame machine repairs, shops can experience significant improvements in workflow speed, product quality, and reduced downtime. This results in increased productivity and satisfied customers, solidifying the importance of incorporating frame machine repair into any well-managed shop’s routine maintenance plan.