Misidentification of parts and incorrect assembly techniques during frame machine repairs are significant issues for auto body shops, especially when handling luxury brands like Mercedes Benz. To avoid inefficiencies, vehicle damage, and safety risks, skilled technicians must meticulously inspect, cross-reference with diagrams, verify genuine parts, and follow structured protocols before installation. Proper assembly maintains structural integrity, facilitates seamless integration of repairs, and is crucial for efficient fleet repair services. Prioritizing safety through correct gear, clean workspace, adherence to guidelines, and specialized equipment protects both technicians and vehicles, ensuring high-quality Mercedes-Benz collision repair services.

“Frame machine repair can be a complex task, often fraught with common errors that even seasoned professionals encounter. This comprehensive guide aims to equip you with the knowledge to navigate these challenges smoothly. We delve into three critical areas: misidentification of parts and how to avoid them, inaccurate assembly techniques with step-by-step guidance, and neglecting essential safety protocols. By adhering to the best practices outlined here, you’ll enhance your frame machine repair skills and ensure optimal results.”

- Misidentification of Parts: Common Mistakes and How to Avoid Them

- Inaccurate Assembly Techniques: Step-by-Step Guidance for Success

- Neglecting Safety Protocols: Best Practices for Frame Machine Repair

Misidentification of Parts: Common Mistakes and How to Avoid Them

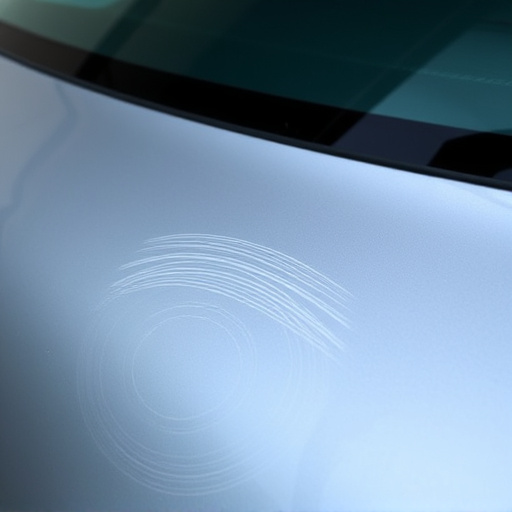

Misidentification of parts is a frequent mistake during frame machine repair tasks, leading to inefficient work and potential damage. Many auto body shops rush into repairs without thoroughly understanding each component’s role in a vehicle’s structural integrity. This often results in incorrect parts selection, especially when dealing with intricate frames from luxury brands like Mercedes Benz. For instance, using the wrong panel or support structure can compromise the vehicle’s safety and handling, causing more harm than good during the restoration process.

To avoid these common pitfalls, it’s crucial to invest time in meticulous part identification. Auto body services should employ skilled technicians who can thoroughly inspect the damaged area, cross-reference with detailed diagrams, and double-check against genuine parts before proceeding. This level of precision ensures that every component replaced is specifically tailored to the frame machine repair, guaranteeing a seamless vehicle restoration experience for clients seeking top-tier auto body services or meticulous Mercedes Benz repair.

Inaccurate Assembly Techniques: Step-by-Step Guidance for Success

Inaccurate assembly techniques are a frequent issue during frame machine repair tasks, leading to subpar results and potential safety hazards. To ensure success, it’s crucial to follow a structured, step-by-step guidance approach. Begin by thoroughly inspecting the damaged frame, identifying all components that require attention. Next, gather the necessary tools and replacement parts, ensuring compatibility with your vehicle model. Before assembly, clean the affected areas to remove any debris or corrosion, creating a solid foundation for accurate work.

Each step of the assembly process should be executed with precision. Start by aligning the frame’s critical points, such as the chassis and body panels, using reference points and measuring tools. Gradually proceed with reattaching components like brackets, mounts, and bolts, following the manufacturer’s specifications for torque and tightening sequence. Regularly double-check your work against a repair manual or workshop guidelines to maintain accuracy throughout the process. Proper assembly not only ensures structural integrity but also facilitates seamless integration of autobody repairs, making it an indispensable aspect of fleet repair services and car damage repair in general.

Neglecting Safety Protocols: Best Practices for Frame Machine Repair

When it comes to frame machine repair, safety should never be an afterthought. Neglecting proper safety protocols can lead to serious accidents and hazardous working conditions, putting both technicians and vehicles at risk. Before beginning any repair task, ensure that all necessary safety gear is in place and properly fitted. This includes wearing protective clothing, eye wear, gloves, and a respirator if required. Additionally, maintaining a clean and organized workspace, as well as following manufacturer guidelines for specific parts, are crucial practices to prevent errors and promote accurate repairs.

For instance, when dealing with vehicle bodywork, such as in Mercedes-Benz collision repair services, adhering to safety standards is paramount. Techniques like welding and painting require specialized equipment and expertise to avoid damage to the surrounding areas of the vehicle. Proper ventilation is also essential during these processes to prevent inhalation of harmful fumes. By prioritizing safety, frame machine repair technicians can not only protect themselves but also ensure the quality and integrity of the vehicle repair services they provide.

When undertaking frame machine repair tasks, being aware of potential pitfalls can significantly enhance your efficiency and safety. By understanding common errors like misidentifying parts, employing incorrect assembly techniques, and neglecting safety protocols, you can avoid costly mistakes. Implement the strategies outlined in this article to refine your skills, ensuring each repair job is executed accurately and securely. Mastering these aspects of frame machine repair will contribute to improved outcomes and a smoother experience for both you and your equipment.